SCADA IED for Utilities

Utilities have requirements, whether by law or by company policy, to monitor and be able to restore electrical power flow as quickly as possible. This has SCADA IED (intelligent electronic devices) power providers like investor owned utilities, cities, and municipals, to focus on collecting data on circuit breaker trips, status, and metering values. The industry has relied on various forms of SCADA IED for utilities to communicate this data back to remote terminal units (RTUs) or communication gateways that then send the data back to a SCADA master. An RTU is a device that collects analog and digital data about a substation and transmits that data back to a SCADA master station. The SCADA master allows operators and engineers to view, control, and analyze power flow throughout a utility operating territory.

Considerations in Choosing a SCADA IED for Utilities

There are substantial considerations when choosing the type of SCADA IED for utilities to communicate this data. Initially, the IED should be “substation grade.” This means that the IED has to be designed with sufficient protection and reliability to protect it against dangerous electrical events that can occur in stations whenever there is a breaker operation. The IED should also be protected at all inputs, including sense inputs, power supply, and communication outputs. To accomplish this, the IED manufacturer has to look at internal isolation levels, surge suppression, and voltage clearances that are normally higher and more conservatively specified than traditional commercial/industrial equipment. Moreover, the manufacturer should be able to substantiate claims, with proper test equipment, to relevant industry standards, such as IEEE C37.90.1 and ANSI C62.41.

The next consideration for the substation SCADA IED is that it supports standard communication protocols that RTUs and communication gateways are able to understand. A communication protocol is the communication language that the equipment uses. While Modbus is considered an industry standard, today, in utility substations, DNP3 and IEC 61850 are the standards that are supported and usually required by most modern RTUs and communication gateways. Meters that specify only Modbus or other industrial or commercial protocols are not sufficient, because while Modbus communication may be available for an RTU, it is generally not easily supported in the installation environment.

Serial (RS485 or RS232) DNP3 protocol has been considered the industry gold standard for safe and reliable communication from a SCADA IED for utilities. However, there are newer requirements for the IEDs to support DNP3 over Ethernet and IEC 61850 over Ethernet. For this reason, modern and capable IED devices, in addition to RS485, must support Ethernet communication that allows users to provide metering data over Ethernet channels using an IP addressable TCP/IP architecture.

When interfacing with older RTUs, there are limits as to the type of input that is acceptable. Many RTUs designed before the newer protocols were popular, utilized “analog” inputs or digital inputs. Analog inputs typically provide data from an analog transducer source. Digital inputs generally provide the status of a digital type of “on/off” source, like an alarm or a breaker position. Modern SCADA IEDs should also have the ability to replace these transducers by providing analog retransmits that will mimic the old transducer outputs. Also, because they are digital, they will be able to provide multiple outputs from one meter, instead of one transducer per meter. The newer meters also have the capability of sending digital signals for alarm or control purposes.

A growing concern for utilities is data security. The Nexus® 1450 meter and the Shark® 250 meter have advanced Cyber Security to protect the utility substation system from hacking and tampering.

Interesting, But What Should I Use?

Electro Industries’ Nexus® 1500+ and Shark® 200 meters are designed to provide useful outputs for SCADA IED for Utilities applications. In the first place, the design is rugged and hardened. It is generally specified for utility applications and is designed to provide a long life and reliable operation.

A base Shark® 250 meter (ideal for distribution stations) has a standard serial port capable of communicating to an RTU via DNP3 over serial. It allows a user to gather “analog” data via a digital means and bring this data back to an RTU, so that the quantities can be viewed by a SCADA master and a control room operator. More advanced applications may call for Ethernet communication, such as DNP3 over Ethernet or the more modern IEC 61850 Ethernet. The Shark® 250 meter also allows the user to choose serial, Ethernet, or both, so that the meter can be utilized with the new implementations, yet still support existing implementations until they are upgraded.

For legacy applications, where there isn’t the budget or desire to upgrade the existing RTU, the Shark® 250 meter can also add up to 8 analog retransmit signals that are either 0-1 mA or 4-20 mA. This allows a user to upgrade analog transducers as they fail, replacing them with digital IEDs that can be upgraded to modern communication architecture at a later time. Status inputs and control outputs are also available, so that most of the traditional substation telemetry applications are fulfilled.

When looking at transmission substation applications, there may be a need for additional performance in an IED. The considerations can include security, fault-analysis, and time-sync options. The Nexus® 1500+ meter would be the suitable solution to improve transmission power distribution system reliability. Moreover, in sophisticated communication schemes, the Nexus® 1500+ meter offers considerable versatility when configuring complex telemetry, especially using its GOOSE messaging capability with IEC 61850 protocol architecture.

Conclusion

When designing a newer infrastructure, substation SCADA IEDs provide a very cost effective and powerful way to enhance substation performance. Choosing the right IED allows a user to not only upgrade technology, but also to plan for future expansion and additional functionality.

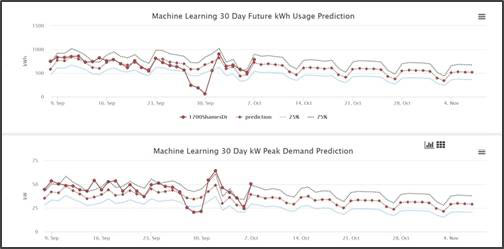

In addition, EIG’s EnergyPQA.com™ Energy Management Cloud solution provides energy analytics and predictions, reducing costs and improving power system reliability. It surpasses traditional Energy Management systems by adding Energy prediction engines and deep insights into power quality.

Popular Products Used with SCADA IED for Utilities

Transmission Stations

Transmission Stations

Distribution

Shark® 250

At The Customer

At The Customer

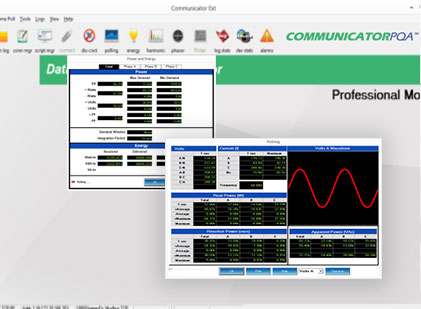

Base Data Collection Software

Base Data Collection Software

EnergyPQA Cloud Energy Management

EnergyPQA Cloud Energy Management

Engineering Services

Engineering Services

Related Products Used with SCADA IED for Utilities

https://www.electroind.com/eigs-energypqa-com-cloud-solution-is-finalist-in-plant-engineerings-2020-product-of-the-year/

https://www.electroind.com/eig-releases-energypqa-com-cloud-based-energy-management-solution/

https://www.electroind.com/facts-you-should-know-about-commercial-energy-waste-in-2019/

https://www.youtube.com/watch?v=XTiIsF1D0Fc

https://www.youtube.com/watch?v=GAVJERWMKeU