Blog

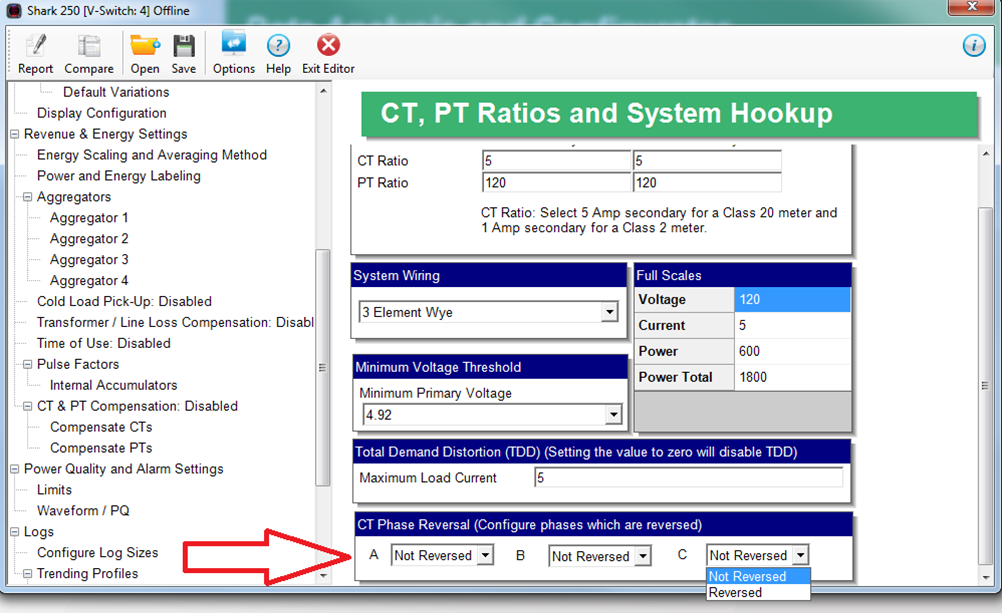

EIG Software Fixes Current Transformer Reversals

One common issue many of our customers face is that the Current Transformers (CTs) are reversed during setup. Reversal in the wiring of the CTs leads to negative wattage being displayed on the meter. This becomes an issue when trying to get accurate readings. Even worse, a potential shutdown may need to occur in order to successfully reverse the wires. Having to perform a shutdown can cause your company both data and financial losses.

Depending on your setup, you may not have enough room, access, or even the ability to reverse the wires. This can make a simple CT reversal difficult and, without a doubt, irritating. EIG provides a simple solution to deal with this common problem that many of our customers face. Our Meter-Manager EXT software allows for configuration of reversed CTs on our Shark® 250 and Shark® 270 energy meters. This quick fix will save you time and stress and stops a potential shutdown.

Learn more about our Shark® 250 meter here:

Learn more about our Shark®270 meter here:

https://www.electroind.com/products/shark-270-revenue-energy-meter/

Learn more about our Meter Manager EXT here:

https://www.electroind.com/products/metermanagerpqa-software-meter-data-collection-server/