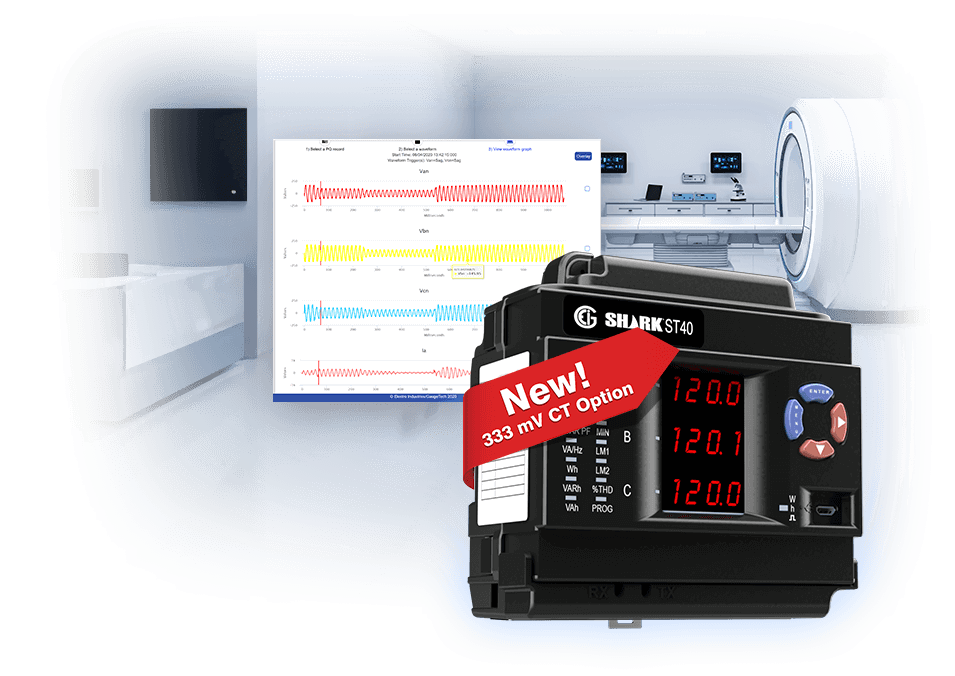

ST40 Compact DIN Rail Mounted Energy and Power Quality Meter

Introduction

Introducing the ST40 DIN Rail Energy Meter

The ST40 DIN rail energy meter is one of the smallest energy and power quality meters in the world. It was designed specifically for DIN rail installation where space is at a premium. The meter provides 0.2% class energy accuracy and advanced power quality features.

Advanced Revenue Meter

- ANSI C12.20 0.2 Accuracy Class energy measurement.

- Traceable watt-hour test pulse for accuracy verification testing.

- Utility block and rolling average demand.

- Transformer Line Loss and CT/PT Compensation.

- Line frequency time sync.

- Sealable voltage and current inputs.

| Measured Parameters | Accuracy% | Display Range |

|---|---|---|

| Voltage L-N | 0.1% | 0-9999 Scalable V or KV |

| Voltage L-L | 0.2% | 0-9999 V or KV Scalable |

| Current | 0.2% | 0-9999 A or KA |

| +/- Watts | 0.2% | 0-9999 Watts, kWatts, MWatts |

| +/-Wh | 0.2% | 5 to 8 Digits Programmable |

| +/-VARs | 0.2% | 0-9999 VARs, KVARs, MVARs |

| +/-VARh | 0.2% | 5 to 8 Digits Programmable |

| VA | 0.2% | 0-9999 VA, KVA, MVA |

| VAh | 0.2% | 5 to 8 Digits Programmable |

| PF | 0.2% | +/- 0.5 to 1.0 |

| Frequency | +/- 0.01 Hz | (45 to 65) Hz |

| THD | +/- 2.0% | 1 to 99.99% |

| Note: Applies to 3 element WYE and 2 element Delta connections. See full accuracy specifications in the ST40 Meter User Manual. Neutral current 2% accuracy. | ||

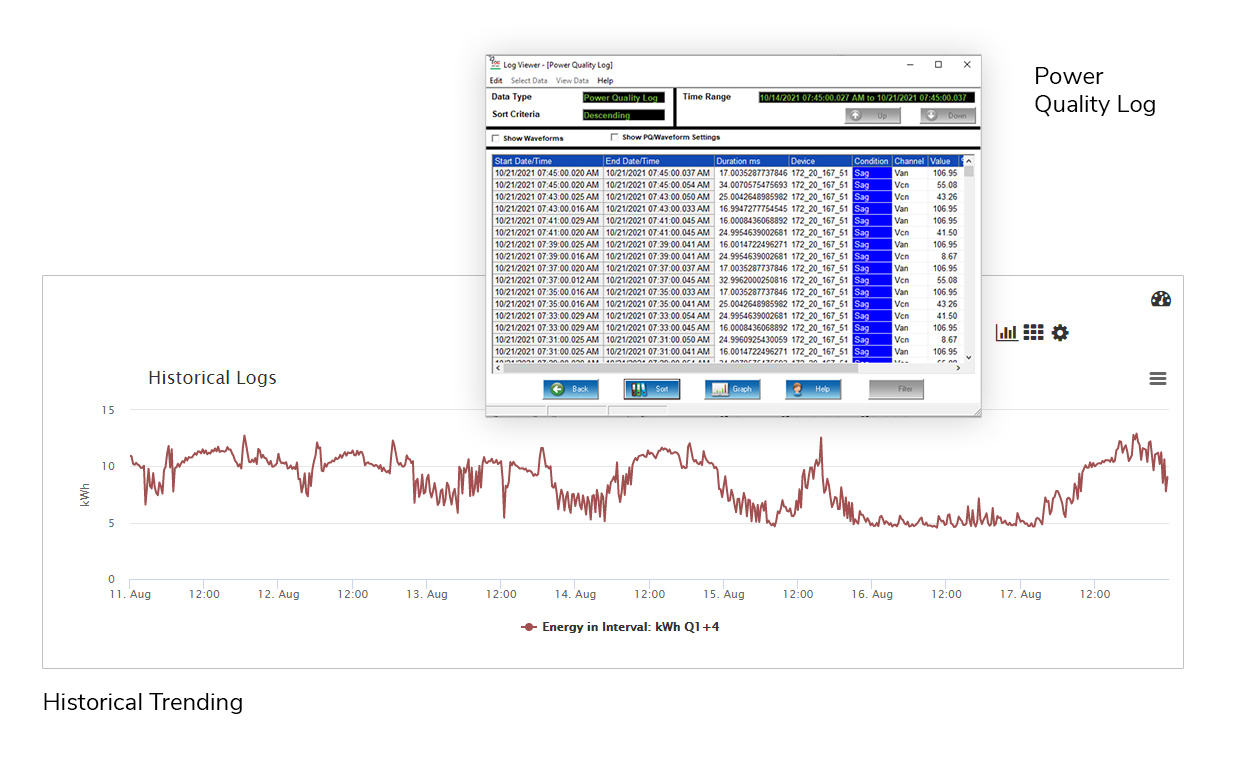

Extensive Data Logging Capability

(V2 and Above)

- Three independent historical trending logs of 64+ parameters each.

- Anti-tampering system events log records actions in the DIN rail energy meter.

- Power quality log provides timestamped magnitude and duration of up to 2048 events.

- Limit alarms log records out-of-limit events for up to eight programmed limits, including voltage and current unbalance.

Upgradable V-Switch™ Technology

- In-field upgrade of meter features.

- Begin with basic features and add more advanced capability when needed.

| Features | V1 | V2 | V3 | V4 | V5 | V6 |

|---|---|---|---|---|---|---|

| Multifunction Measurement | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Basic Data Logging | ✓ | ✓ | ✓ | |||

| Intermediate Data Logging | ✓ | |||||

| Advanced Data Logging | ✓ | |||||

| Harmonic Analysis | ✓ | ✓ | ✓ | ✓ | ||

| TLC and CT/PT Compensation | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Limit Functions | ✓ | ✓ | ✓ | |||

| 64 Samples per Cycle Waveform Recorder | ✓ | |||||

| 512 Samples per Cycle Waveform Recorder | ✓ |

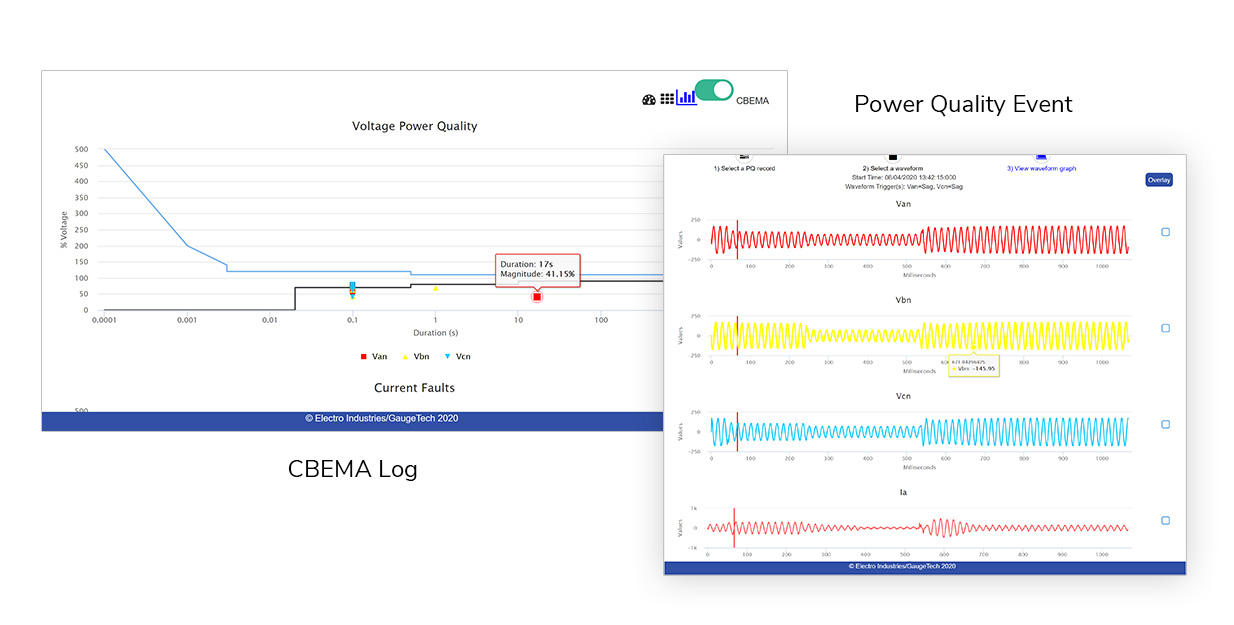

Power Quality Measurement

Power Quality Measurement

- Up to 512 samples per cycle waveform recording.

- Pre and post event waveform recording is provided.

- Waveform power quality triggers can be based on a ½ cycle updated RMS.

- Independent CBEMA and SEMI F47 logs are stored for quick power quality analysis.

- Harmonic recording to the 40th order and harmonic analysis to the 255th order.

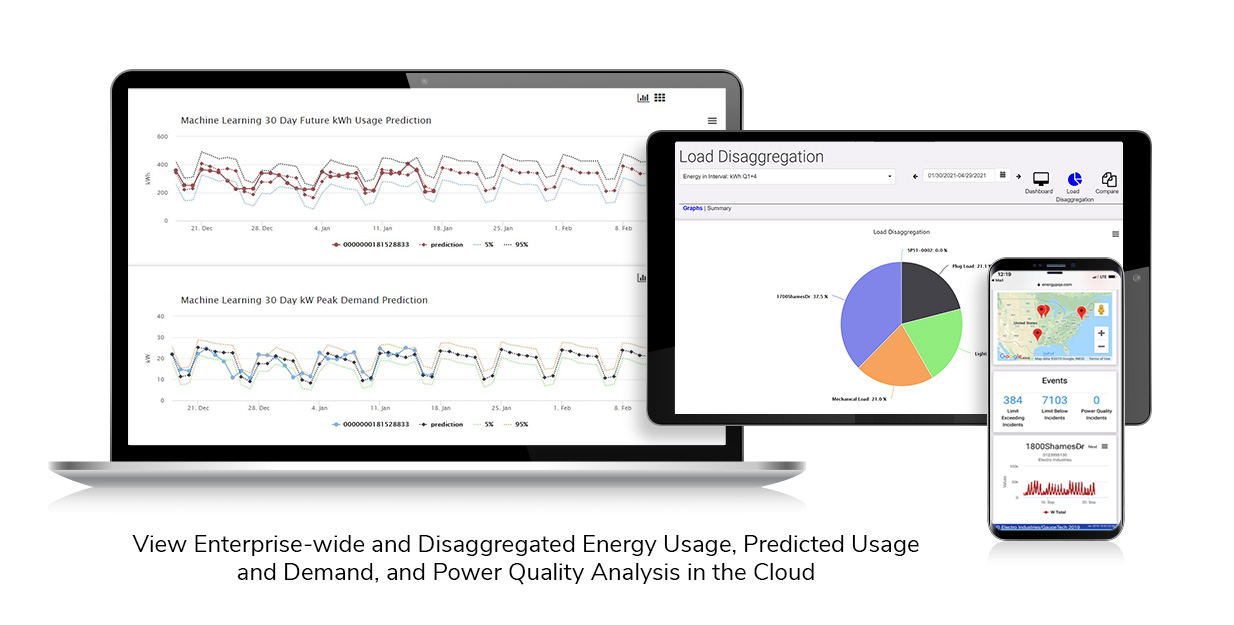

Reduce Energy Costs Using EIG’s EnergyPQA.com® System

Integration with the EnergyPQA.com® Energy Management System

- Compare energy usage and demand across meters and facilities.

- View predicted usage and demand for resource allocation and planning.

- Receive alerts of predicted peak demand in advance to avoid costly demand penalties.

- Gain deep insights into facility and enterprise power quality.

- Receive reports of least efficient and most at risk facilities and circuits to focus efficiency and power quality improvements where they will have the most impact.

Applications

Applications

- Machine level monitoring.

- Power quality metering.

- Commercial submetering.

- Cost allocation and sub-billing.

- Medical and industrial equipment monitoring.

- Solar, wind, and micro-turbine power generation metering.

- Applications where installation space is limited.

Downloads

Downloads

Tech Documents

Generic Specifications

Ordering Guide

Youtube Videos